Servo Motor Suppliers in Nagpur, Servo Motor Repair Services

S N Automation is the Leading Servo Motor Suppliers in Nagpur, Dealers, Traders, and Repair Services in Nagpur. The design of our servo motors is to offer precise speed, position, and torque management to ensure a smooth operation and optimum performance in CNC machines, robotic systems, packaging machines, and other automated machines. We have been providing Mitsubishi, Hass, Siemens, and Fanuc Servo Motor Suppliers, dealers and traders with certified, high-quality products. We are trusted as a partner in servo motor solutions in Nagpur as well as beyond, due to our dedication to providing innovative, quality, and customer satisfaction solutions.

Servo Motor Repair Services in Nagpur

We can repair and identify problems associated with winding and overheating, less powerful torque, and vibration with state-of-the-art test tools and authentic replacement parts. Servo Motor Repair Services in Nagpur offering professional Services of Repairing Servo Motors in Nagpur, as it is a company that will guarantee effective and successful repairing of faulty or broken servo motors.

Servo Motors Dealers in Nagpur

Our group helps our customers to choose the appropriate servo motor to fit their application, and also gives them professional advice, delivers on time and provides after-sales services. Servo Motors Dealers in Nagpur have high quality, which makes them dependable, accurate, and strong and therefore have a smooth motion control and efficient performance.

Servo Motor Traders in Nagpur

We have a team of skilled people who assist you in selecting the correct servo motor to use in your project, give technical guidance and deliver the same on time. As the Servo Motor Traders in Nagpur collaborate with our reputed suppliers so that we can obtain real, faithful motors that are engineered to achieve high precision, smooth movement, and long life, even with heavy industrial loads.

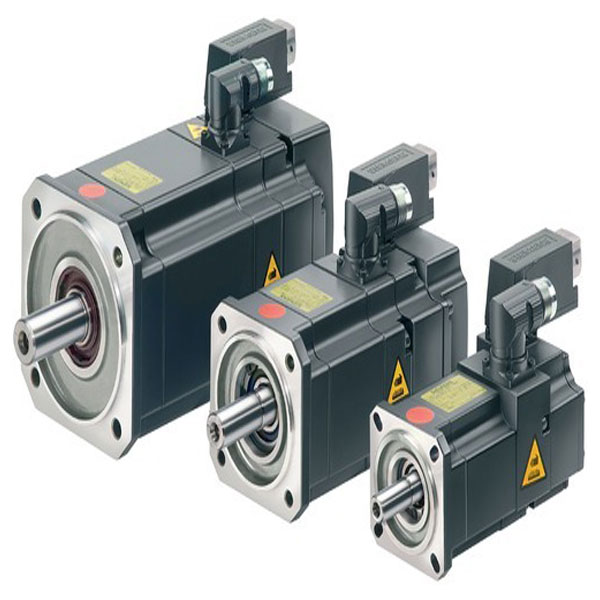

Types of Servo Motor

We are Servo Motor Suppliers in Nagpur and following are various types of Servo Motor we offer.

- Siemens Servo Motor: These motors are popular in automation systems, process control and robotics, and they offer smooth movement, real-time feedback and easy integration with PLCs and control systems, resulting in high productivity and efficiency.

- Fanuc Servo Motor: Fanuc servo motors are designed as high-performance automation and robotics equipment used in automation and robotics that require accuracy in motion, maximum speed, and reliable feedback.

- Mitsubishi Servo Motor: Integrated Servo Motor are ideal in CNC machines; robotics and automation systems where they offer smooth operation, accurate speed, position and torque control to enhance optimized performance and consistent productivity in industrial usage.

- Hass Servo Motor: They are also known to have long life and solid design, hence control of speed and torque is accurate, suitable in CNC machines and milling, grinding, among other automated processes of manufacturing, where reliability is a major consideration.

Technical Specification of Servo Motor

As Servo Motors in Nagpur, we have added below a table of technical specifications for this Servo Motor.

| Specification | Mitsubishi Servo Motor | Hass Servo Motor | Siemens Servo Motor | Fanuc Servo Motor |

|---|---|---|---|---|

| Control Accuracy | High | High | High | High |

| Torque Control | Precise and stable | Accurate and consistent | Accurate with real-time feedback | High-precision torque control |

| Speed Control | Smooth operation, consistent performance | Smooth, controlled speed | Precise speed control, optimized for automation | Fast, smooth, and precise motion |

| Durability | Robust and reliable | Long-life, industry-grade | Durable, suitable for industrial automation | Reliable in high-speed industrial applications |

| Integration | Compatible with Mitsubishi CNC and automation systems | Compatible with Hass machinery and automation | Easy integration with PLCs and control systems | Compatible with Fanuc CNC and robotic systems |

| Energy Efficiency | Optimized for consistent performance | Efficient for long-term operation | Energy-efficient and reliable | Efficient for high-speed automated manufacturing |

| Operating Temperature | -20°C to 50°C | -20°C to 50°C | -20°C to 50°C | -20°C to 50°C |

Benefits of Servo Motor

We are Servo Motor Dealers and Traders in Nagpur and below are some of the key benefits of this Servo Motor.

- Energy Efficiency: AC Servo Motor and Driver Economizes power by regulating energy production based on the load needs.

- Rapid Response: Has high acceleration and deceleration, and it enhances the speed of production and the overall functioning of the system.

- Durable and Reliable: Servo Motors and Drives Structured to be used in harsh industrial conditions over a long period of time.

- High Precision Control: Servo Automation offers precise speed, position and torque control of CNC machines, robotics and automation systems.

- Smooth Motion Operation: DC Servo Motor Lessens vibration and mechanical stress, assures constant and smooth operations of equipment.

Applications of Servo Motor

As Servo Motor Repair Services in Nagpur, our Servo Motor are widely used in following key areas.

- CNC Machines

- Robotics and Robotic Arms

- Packaging Machines

- Conveyor Systems

- Printing Presses

- Textile Machinery

- Automated Assembly Lines

- Injection Molding Machines

- Medical Equipment (e.g., surgical robots)

- Industrial Control and Automation.

Why choose us?

- Knowledge and skills: Experience in industrial automation and servo motors.

- Quality Products: We deal with robust, accurate and dependable servo motors of well-known brands such as Mitsubishi, Hass, Siemens and Fanuc.

- Personalized Solutions: Our staff assists you in choosing the appropriate motor based on the torque, speed and the area of use.

S N Automation is the Leading Servo Motor Suppliers, Dealers, Traders, Repair Services in Nagpur. Offers servo motors of superior quality, integrating precision, reliability, and efficiency to fulfill the high standards of contemporary industrial automation. Our servo motors guarantee smooth movements, precision performance, and prolonged performance since from CNC machines and robotics to packaging lines, and automated assembly systems, the motors will ensure smoothness in motion and precise performance. Contact us now!

FAQ’s

Ans: A servo motor is an electric motor that is typically employed to control the speed, position, and torque of a machine with high precision, in CNC machines, robotics and automation systems.

Ans: Their use is common in CNC machines, robotics, packaging machines, conveyor systems, printing presses, textile machinery, automated assembly lines, injection molding machines, medical equipment and industrial automation.

Ans: It is chosen based on the torque, speed, power needs, and the nature of a particular industrial application. Our professionals advise clients to make the right choice on the motor.

Hi there! 👋

Fill out the form below to start a conversation with us on WhatsApp.

Hi there! 👋

Fill out the form below to start a conversation with us on WhatsApp.